Ensuring the reliability of 3D-ICs

30. January 2025

While discussions around infotainment and Advanced Driver Assistance Systems (ADAS) are shaping the future of mobility, it is essential to focus on the core technologies powering electric vehicles (EVs). At the heart of these innovations lies power electronics, which control motor functions, enable regenerative braking, and optimize charging processes – both at home and on the go.

Key technologies in this field include Insulated Gate Bipolar Transistors (IGBTs) and Silicon Carbide (SiC). In particular, SiC has emerged as a game-changing technology, significantly enhancing efficiency and performance. Pioneering companies like Tesla are driving the widespread adoption of SiC-based solutions.

Enhanced efficiency with SiC in EV drivetrains

The role of power electronics in EVs is most evident in the drivetrain. Modern EVs rely on AC motors due to their superior efficiency compared to DC motors. To operate AC motors, EVs require inverters that convert DC power from the battery into AC power. This is where SiC transistors play a crucial role:

- Higher voltage tolerance and operation at higher frequencies.

- Reduced heat generation, enabling more compact system designs.

- Lower weight and improved energy efficiency, resulting in extended range and cost savings.

Thanks to these advantages, SiC transistors are a cornerstone of next-generation EV powertrains.

SiC in fast-charging stations

The benefits of SiC extend beyond vehicles and into fast-charging infrastructure. High-power DC fast chargers (500-600 kW), which convert AC power into DC, require highly efficient rectifiers. SiC-based solutions offer:

- More compact designs compared to traditional silicon-based alternatives.

- Higher energy efficiency and lower operational costs.

These features are critical for the expansion of EV charging networks, which are accelerating due to both industry demand and regulatory incentives.

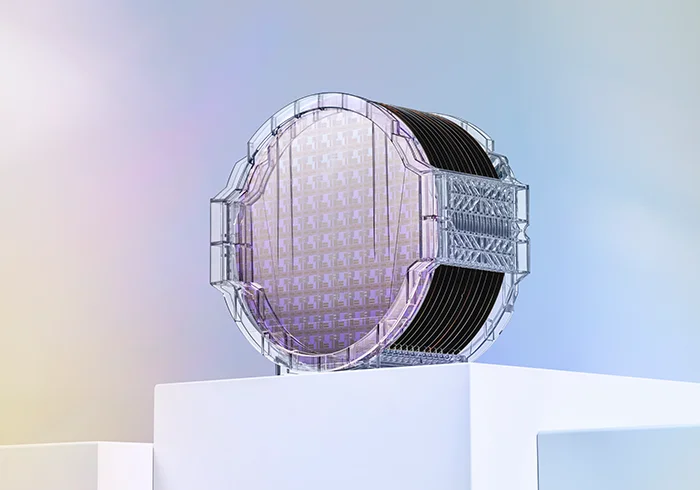

How Soitec and SmartSiC® are shaping the future

Soitec is a leading producer of SiC substrates, essential for components like inverters. Using its proprietary SmartCut® technology, developed by CEA-Leti in France, Soitec transfers an ultra-thin SiC layer onto a substrate, creating SmartSiC® for automotive applications. This innovation:

- Reduces manufacturing costs and energy consumption.

- Sets new industry standards for SiC component production.

Soitec’s new facility in Bernin, near Grenoble, is set to produce 500,000 SiC wafers annually. This strategic investment not only strengthens Soitec’s market position but also enables companies like Active Business Company to integrate cutting-edge SiC technologies efficiently and future-proof their innovations.