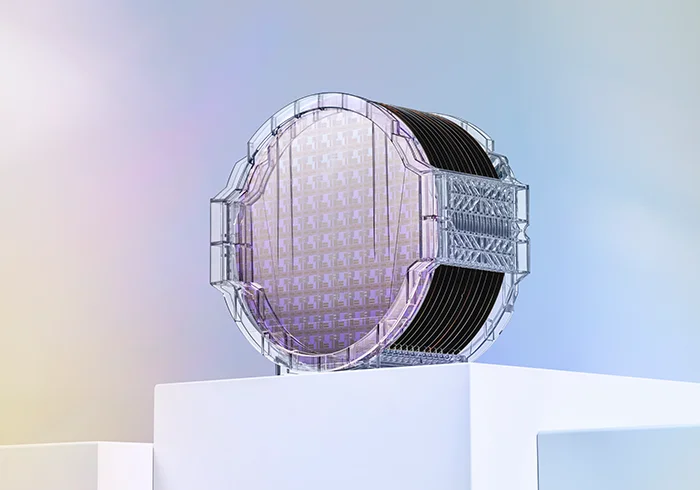

Silicon Wafer

Silicon Wafer – Precision and versatility for high-tech applications

Silicon wafers form the foundation of modern semiconductor technology and are indispensable in numerous high-tech industries worldwide. Active Business Company GmbH (ABC GmbH) offers a comprehensive range of high-quality silicon wafers - from standard solutions to custom-tailored specifications.

We provide wafer diameters from 1” to 18” and thicknesses ranging from 20 µm to several millimeters, including standard thicknesses according to SEMI and JEIDA standards.

With our flexibility and ability to implement custom designs, we create the optimal foundation for your projects.

What is a Silicon Wafer?

Silicon wafers are disks made of highly pure, monocrystalline silicon in various thicknesses. They serve as the base material for semiconductor components and stand out due to their excellent electrical and mechanical properties. This makes them indispensable in the semiconductor industry and beyond.

Our specifications

Diameter

25 mm to 450 mm

Crystal Orientations

<100>, <110>, <111>, and more upon request

Thickness

All thicknesses according to SEMI standards, customizable from 20 µm to several millimeters or even centimeters

Surface Types

SSP (Single Side Polished), DSP (Double Side Polished), etched, as-cut

What types of Silicon Wafer do we offer?

Manufacturing processes

1. CZ Wafers (Czochralski Process)

These wafers are produced using the Czochralski method and are known for their stability and uniform crystal structures. They are ideal for standard semiconductor industry applications and are the most commonly used wafers.

2. MCZ Wafers (Magnetic Czochralski Process)

The MCZ method is a variation of the CZ method, where a magnetic field (vertical or horizontal) is applied to the molten silicon surface. This enables larger crystal diameters and controls convection flow, reducing oxygen concentration.

3. FZ Wafers (Float Zone Process)

FZ wafers, produced using the float-zone method, offer maximum purity and are optimal for precision applications such as MEMS, diodes, RF devices, IGBTs, and thyristors.

Quality grades

1. Prime Grade Wafer

Prime grade wafers are the highest quality silicon wafers, meeting the strictest SEMI standards. They are used in high-end semiconductor applications where top quality and precision are crucial.

2. Test Wafer

Test wafers meet lower requirements than prime wafers and offer a cost-effective alternative for development or testing purposes.

3. Reclaim Wafer

Reclaim wafers are recycled wafers that have been reprocessed through cleaning and polishing for reuse in testing or production.

We are happy to provide personalized advice on the different wafer types to find the best solution for your application.

Applications for

Silicon Wafer

Our silicon wafers are used across various industries, including:

- Automotive & Aerospace: Sensors and electronic control systems

- Mechanical Engineering: High-precision technical components

- Semiconductor Manufacturing: MEMS, diodes, RF devices, IGBTs, and more

- Optics & Watch Industry (Optoelectronics): Wafers for optical and mechanical precision

- Medical Technology: Components for diagnostic and therapeutic devices

- Research & Development: Universities, Fraunhofer Institutes, and laboratories

Thanks to our broad product range and the ability to produce specialized wafers, we reliably meet the requirements of diverse industries.

Why choose ABC GmbH?

- Top Quality: Silicon wafers from leading international manufacturers

- Flexibility: Solutions for small and large production volumes

- EU-Based Supply: Duty-cleared goods with fast, free delivery

- Personal Consultation:

A dedicated contact person for your specific needs - Full-Service: Since 2006, we have provided a wide range of services – including coating and dicing – through our extensive, global, and continually growing network, which includes renowned top-tier manufacturers.

Our Silicon Wafers – Your benefits

Our silicon wafers offer the highest precision and reliability – the foundation for your high-tech projects. Whether for prototype development or mass production, we provide tailored solutions for every development or manufacturing phase.

Our customers' success is our success.

We stand for direct communication, personalized consulting, and strong partnerships.

Request Silicon wafers now

Our customers’ success is our success. We stand for direct communication, personal consultation, and strong partnerships. We would be happy to provide you with a customized quote.

ABC GmbH is your supplier for silicon wafers and specialized solutions. As a trusted partner in the semiconductor industry, we offer high-quality products and tailored services.